G&S Valves Ltd

Manufacturing Bespoke Engine Valves Since 1946

Technical Information: Physical Properties

Hot Forming Temperature, Thermal Conductivity, Specific Heat Capacity and Thermal Expansion |

||||

Material |

Hot Forming Temperature |

Thermal Conductivity W/(m.K) |

Specific Heat Capacity J/Kg. K |

Mean coefficient of Thermal Expansion * |

214N (349S52) |

1150-950 °C |

14.5 |

500 |

100 °C 15.5 |

1.4882 |

1150-950 °C |

14.5 |

500 |

100 °C 15.5 |

EN24 - (817M40) |

|

37.7 |

460 |

|

EN52 - (401S45) |

1100- 900 °C |

21 |

500 |

100 °C 10.9 |

EN59 - (443S45) |

|

|

|

|

Nimonic (80A) |

1150-1050 °C |

13 |

460 |

100 °C 11.9 |

Specific Heat is the ratio of heat required to raise the temperature of a certain weight of material by 1 Deg C to that required to raise the temperature of the same weight of water by 1 Deg C

* Note - To find the expansion at 300 Deg C of a valve with a stem diameter of 0.275" in 214N material (Assuming the stem diameter was measured at 20 Deg. C) the temperature difference is (300 Deg C - 20 Deg C) = 280 Deg C stem diameter x temperature difference x coefficient of thermal expansion = Expansion of Valve ie:0.275 x 280 x 0.0000175 = 0.0013"

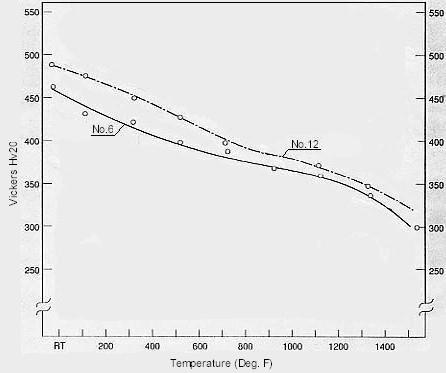

High Temperature Hardness (Cobalt Based Deposit No.6 & No.12)

Hardness |

||

Material's (Valve Steels & Tips) |

Rockwell 'C' Scale |

Vickers '30' |

214N - (349S52) |

30 HRc |

318 Vickers |

1.4882 |

30 HRc |

385 Vickers |

EN52 (401S45) |

25 - 31 HRc |

437 - 395 Vickers |

EN59 (443S65) |

28 - 36 HRc |

283 - 353.5 Vickers |

EN24 (817M40) |

22 - 30 HRc |

248 - 302 Vickers |

Nimonic (80A) |

32 HRc |

Vickers |

Armored Seats – Cobalt based deposit – Grade 6 |

38 - 42 HRc |

371 - 412.5 Vickers |

Tips – Cobalt based deposit – Grade 12 |

46 - 50 HRc |

Vickers |

EN24 (welded tips) |

52 - 54 HRc |

541 - 576 Vickers |

1.3343 (welded tips) |

Approx. 58 HRc |

Vickers |

Volumetric Weights |

||

Material +/- 0.5 Grams |

Volumetric Weight |

|

214N - (349S52) |

7.74 g/cc x (16.38706 x Volume) |

|

1.4882 |

7.81 g/cc x (16.38706 x Volume) |

|

Nimonic (80A) |

8.19 g/cc x (16.38706 x Volume) |

|

EN59 (443S65) |

7.74 g/cc x (16.38706 x Volume) |

|

EN52 (401S45) |

7.61 g/cc x (16.38706 x Volume) |

|

EN24 (817M40) |

7.84 g/cc x (16.38706 x Volume) |

|

© Copyright G&S Valves 2014

Website Design by heatherdesign.co.uk